Strip edge processing by metal-cutting to optimize the tube weld seam

Exhibitor

Heinz Berger Maschinenfabrik GmbH & Co. KG

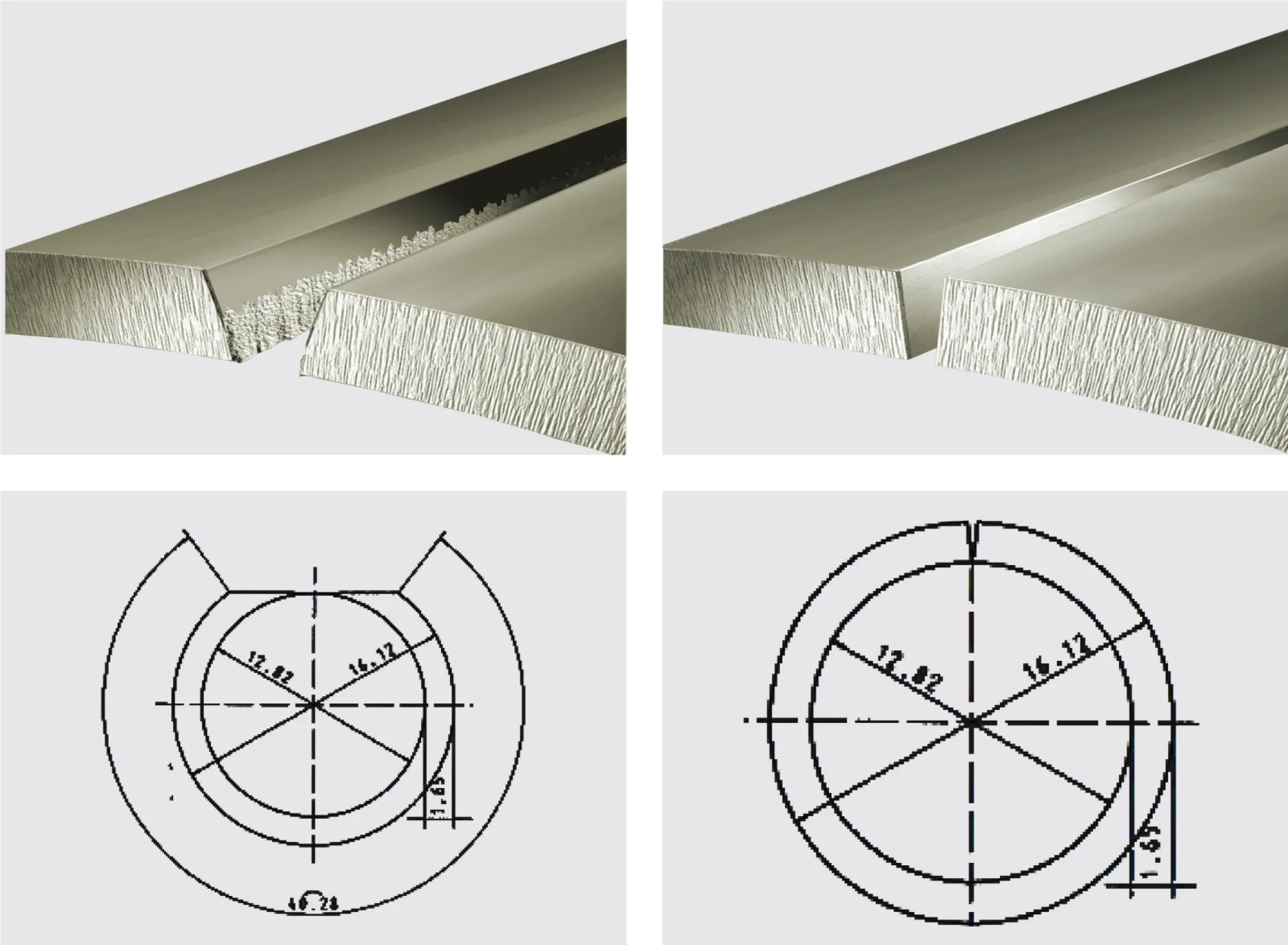

The basic strip material is usually longitudinally split strip (slit strip). Only <35% of the edges are really cleanly cut, the larger portion is broken off and is not clean, i.e. irregular in terms of straightness, angle and structure, and coatings may interfere with welding. The thicker the wall thickness and the smaller the tube diameter, the greater the V-angle at which the round pipe edges meet. The cross section to be welded that collides with each other becomes smaller and smaller and thus the area to be liquefied necessarily larger. As a result, the upsetting zone and the upsetting force occurring immediately after welding become larger. This results in ever greater weld seam elevations, which have to be planed off at the top and inside surface in a very time-consuming process.

With strip edge trimming by metal-cutting the edges become evenly clean and straight and also have their inner structure on the surface. The edges are machined at an adjustable angle so that the V-angle for welding is reduced and coatings on the strip edge are removed. The colliding cross section of the edges is maximized, so that a smaller volume of material has to be liquefied.

Strip edge before (left) and after (right) strip edge trimming by metal-cutting